As we have continually searched for inspiring businesses/entrepreneurs who embody the great American D.I.Y spirit for this series, there have been several common themes that we have uncovered when seeking a compelling story…

One being that each entrepreneur can be described as innovative, however not in the 21st Century Silicon Valley regard…the first grouping of Drawing Inspiration entrepreneurs have rolled out very simplistic-functional offerings. As functional as these ideas may be, they are profound in their own right regardless of technological prowess.

Secondly, each business and/or entrepreneur with a unique story to tell has surfaced from relationships in the creative world. There seems to be validity in the theory of “six degrees of separation”. Thus far, we have had the opportunity to bring forth two inspiring brands with less known stories through the power of Word of Mouth. Each of the brands that we have featured for this series are optimizing their output of Word of Mouth with an increasing focus on “Opinion Leader” marketing vs. the traditional mega-budget, multi-layer agency launch. I can certainly appreciate the value in the “Do It Yourself” spirit and the ability to organically drive what is arguably the most powerful variable in all brand building (Word of Mouth) through relationships.

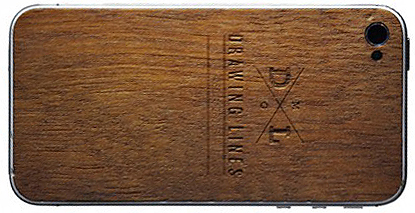

For this Drawing Inspiration entry we were able to host a fireside chat with Matt Turner, the co-founder of Material 6. Material 6 is a brand that manufactures hand crafted, specialized Apple product replacements. Enjoy and for more information check out Material 6.

Interview by: Ryan King

Your primary product offering is based off of enhancing the iPhone 4 and iPhone 4S…how did the idea of creating hand crafted iPhone backs come about?

When I had the iPhone 3G, I spent a bit of time looking around at the case offerings out there – especially since our other product spec.dock uses Apple dock inserts. We were frequently asked about cases that were compatible with these inserts and our docks. My favorite that I came across in that research was the solid wood cases made by Miniot. I really appreciated the combination of wood, glass and aluminum, and came close to getting one if not for the added bulk.

When the iPhone 4 came out, I quickly realized that the glass back wasn’t going to do it for me – I would’ve spent a year or two setting the phone on napkins to try and keep it from getting scratched or broken! So, naturally, wood was the first thing that came to mind when I started contemplating changing the back panel from the original glass…

How much time did you spend in the conceptual and research/development phases before launching Material 6 as a company?

Making the initial piece, which lived on my iPhone 4 for some time, was really an exercise in precision woodworking – especially with the tools we had on hand at the time. While we have a full fabrication shop, we didn’t have a few of the tools we have now to make this process much easier.

We spent a good three or four months working on sourcing components and high quality wood veneers, trying out and field testing different finishes and trying to make the production aspect as efficient and repeatable as possible. We only wanted to offer the Material 6 product if it was going to hold up to the standards we’ve always held ourselves and our products to.

Based on researching this fairly new industry, it seems as if Material 6 has been the first to come to market with this product. How would you describe Material 6 and what you are doing in a new market place?

We were definitely first to market with this product, although competitors came on pretty quickly once the idea was released into the wild…Our concept with this product from the beginning was to emphasize the handmade, precise and high-quality nature of the product being offered. We made sure to position the product, company name, logo, website, pricing, customer service, warranty, return policy – basically anything we could think of as such.

Since we have been making accessories for Apple products for over six years now, we know that they (Apple) are never content to stay with one design. Making a great product was just as important as creating a great brand, as we knew from the launch that we would need to keep up and offer new products to work with Apple’s changing handset design.

What we made sure not to do was to make price a motivating factor with sales, discount codes, promotions,etc. as we also knew in advance that we were going to approach brick and mortar stores to sign on as resellers. We spend all of our time on the quality of each piece and each customer experience, and the business comes from great press and word of mouth.

Currently, the Material 6 iPhone replacement backs are made of wooden inlays…Do you have any plans of expanding the product line or to use other materials?

Initially, we considered other materials such as carbon fiber and possibly some metals – we had samples of brass and copper in house to work with. However, the initial thought was to use wood and we’ve really had great success with it. I have always really liked companies that do one thing and do it exceedingly well, so I wanted to stick to that formula for as long as the market remained interested in what we were offering!

As I mentioned though, we’re going to have to keep it moving when the iPhone 5 comes out, so we have some plans that involve metal as a possible choice.

One of the appeals to the product offering in my opinion is the actual materials and sourcing of unique wood grains from around the world. What is the process for discovering and sourcing various and exotic grains?

We appreciate that you noticed! The other companies offering anything along the lines of the Material 6 replacement backs are sticking to Cherry, Walnut, Mahogany and Bamboo; while we have a huge list of woods to pull from, and we recently expanded our capabilities so we are now able to manufacture our own veneers from raw lumber. So the sky is really the limit!

When we started, we were going to offer three new woods a month to limit the choices and increase the “gotta get it before it’s gone” factor, but quickly realized this wasn’t the way to go. So, we started adding three at a time periodically instead, with a max of nine at a time, and we just pick ones we like and see how they sell.

The all-time winner to date is still South American Rosewood, but I really love the Ebony Macassar, Lacewood and Roble Burl (which we ran through our supplier’s entire stock of). Poor performers are discontinued when we sell through or just need to go to be replaced by something fresh. We have our eyes on some new species moving forward, but we like to keep it a surprise until they launch…

In addition to the clean and aesthetically pleasing raw wood grain look, it seems that Material 6 has already launched some diverse and legendary artist editions. What is the story behind how the artist collaborations come about with guys like Benny Gold?

I remember listening to Neal Boortz one day back in college telling the story of watching a skateboarder walk down the aisle in a commercial plane with his board in hand while he (Neal Boortz) thought of what a loser the skater was going to become from spending all his time on a useless “fad” pastime…I was so riled up I called in, but of course never got through. The point is though, that’s (skateboarding style & relationships) how the Benny Gold collaboration and the Cukui collaboration came to be, as well as how our website was built, all of our photos produced, and also has a lot to do with the style of the product itself. In addition to hard work, many of the connections come from the world that skateboarding has built around myself and my friends.

Now that we’ve had some notoriety for the collaborations, we are getting requests and interest from artists outside of the circle that we’re currently working with. I guess it really does end up being who you know in some cases…

I couldn’t help but notice Eric Koston rocking one of your replacement backs on Instagram…Beyond the list of heavy hitters in the artists series, are there any other lifestyle “celebrity” endorsers?

Well, we know for sure that Koston has one, as does Paul Rodriguez (P. Rod), Justin Brock and a lot of the other Nike skate guys, but we’ve definitely had some celebrity purchases. My favorite so far was the phone call from Zach Galifianakis just because of how normal he was on the phone! That guy is hilarious…We also have had Material 6 products in the gift bags at the Billboard Awards this year. We were able to get them out to a really great list of 120 artists, so I keep checking for photos of them rocking the product. I can’t just call them up and ask, but I know they are definitely floating around in celebrity hands around the world, which is really exciting for us.

Do guys like Eric Koston, P. Rod, and Zach Galifianakis have custom engraved/design Material 6 backs or are the sticking with raw wood grains?

Interestingly enough, P.Rod and Zach both got blank backs and for Koston we actually did a custom high-polish piece for (that’s the only one we’ve ever done, as polished equals scratches, which is one of the reasons for replacing the glass back with wood in the first place). It seems like the engravings are kinda like tattoos – unless the engraving means a lot to the customer, they’ll typically just go with the blank piece. I’d say we engrave about 10-15% of the orders.

Interestingly enough, P.Rod and Zach both got blank backs and for Koston we actually did a custom high-polish piece for (that’s the only one we’ve ever done, as polished equals scratches, which is one of the reasons for replacing the glass back with wood in the first place). It seems like the engravings are kinda like tattoos – unless the engraving means a lot to the customer, they’ll typically just go with the blank piece. I’d say we engrave about 10-15% of the orders.

Right now the focus is primarily on your excitement of Apple products, specifically the iPhone 4 and iPhone 4S. Do you plan to expand your product offering to other devices or manufacturers in the future?

With spec.dock and with Material 6, we’ve stuck to Apple products due to their impeccable design, product cycles and market share, but we’re definitely open to other devices. It seems like a new Android handset comes out every week, but we would definitely consider expanding the line as we grow.

What are the differentiating factors that set Material 6 apart from similar product offerings and/or brands?

My business partner and I truly are craftsmen, who have been fabricating and woodworking for our entire lives, so to me that’s really the difference. I feel that it shows in our attention to detail and the quality of our offerings, but also in our customer service, since we want every customer to be as proud of what they’ve bought as we are of what we made. Seriously – I’ve sent more than one customer a full replacement for their order along with a return label simply because they wanted a different grain pattern than what they received. We’re that serious.

As I mentioned before, we’ve been building a brand that has far-reaching plans and goals, so really hope to be a company that our customers can rely on to support the current product and products to come for years down the road.

What would you like for Material 6 to accomplish in the future?

Kinda answered mysteriously above, but let me know if these answers spark any other questions…it’s not that often that I get to go on a rant about what we’ve done over here, so I appreciate the opportunity!

Photos by: Ryan Flynn